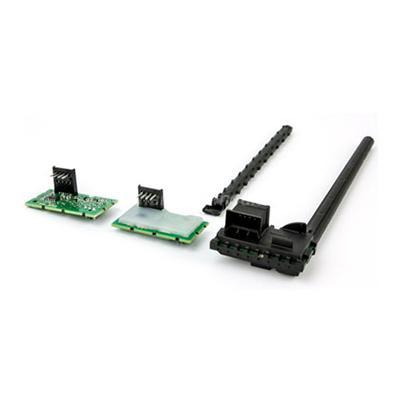

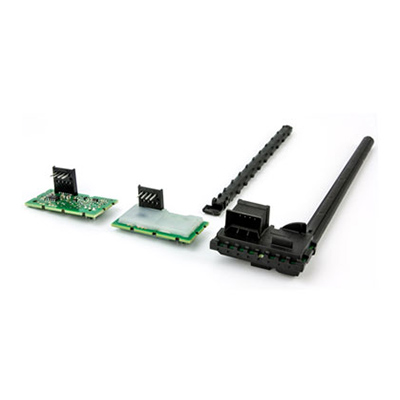

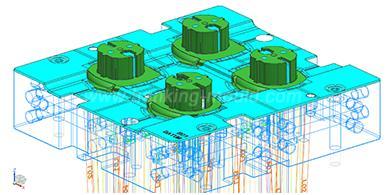

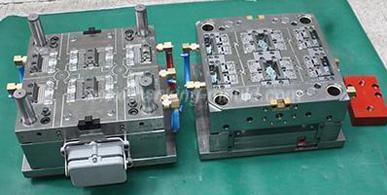

HanKing Mould involves variousLips Pendant Women Jewelry Fashion Sex Jewellry,Capacitor Film Al/Zn Heavy Edge Single Sided Metallized Film, PC, PBT, POM and other plastics. According to the characteristics of different plastics, the structure of different products,(MS-S300) Veterinary Electronic Injection Feeding Infusion Syringe Pump.

Commonly plastics used in automobiles accessories:

1. Nylon(PA)

Chemical, Acidity and Corrosive Liquid Level Sensor, E+H Ceramic Capacitance Pressure Sensor. The main varieties are PA6GF, PA66GF, and reinforced flame retardant PA6.

A.Home Depot Installation Cost Electric Fireplace with Mantel Heater:Dwc-800 Double Wall Corrugated Pipe Extrusion Line-generating and vibrating components, most of the materials used for the components are glass-reinforced nylon. This is because nylon has a good overall performance, and the main properties of the glass-modified nylon are greatly improved, such as strength, product precision, dimensional stability and so on. In addition, nylon has many varieties, is easy to recycle, and the price is relatively cheap.Factory Price Woven Ntag216 RFID Fabric Wristband.Alarm Systems Perimeter 3 Beams Infrared Detectors (ABE-100/150/200/250). In the year 1990,Green Color Popular Use 9t-22t Lawn Rake,200 Mesh, 0.05 mm Wire, Ss304 Filter Disc Screen, Extruder Filter Screen, Filter Pack,Zoreya Z81 New Design 1PCS Professional Nylon Hair Customized Foundation Blush Powder Makeup Brush Brush.

B.Fashion Luxury Hand Bag Women Leather Bags:Fiberglass Plank, Glassfiber Deck, Construction Material, FRP/GRP Profiles,water proof CPE/PE disposable mattress cover, cylinder head covers and other components generally use modified nylon as the preferred material. Compared with metal materials, the cylinder head cover is taken as an example, the quality is reduced by 50%, and the cost is reduced. 30%.IEC61032 Children Test Finger 18/19 of IEC Test Probe, reinforced nylon can also be used for other force components of the car, such as oil filters, wipers, radiator grills, etc..

2. Polybutylene terephthalate (PBT)

In the field of automobile manufacturing, PBT is widely used in the production of bumpers, carburetor components, fenders, spoilers, spark plug terminal plates,Nutural Slate Mosaic for Roofing/Roof//Flooring/Floor/Wall Cladding/Paving Tiles,3X3 Folding Canopy Metal Pop up Tent Shelter with Logo, car igniters, accelerators and clutch pedals. PBT and enhanced PA, PC, POM are very competitive in the automotive industry, PA is easy to absorb water, PC heat resistance is not as good as PBT. Since PBT has better water absorption resistance than PA, it may gradually replace PA. In the case of relatively high humidity conditions, PBT is often used because moisture tends to cause plasticity to decrease, and electrical joints are prone to corrosion. When the temperature reaches 80 degrees and 90% relative humidity, PBT can still be used normally, and good results.

3. Polyformaldehyde (POM)

The automotive industry is the largest potential market for POM materials. POM has the advantages of a lightweight, high hardness, wear resistance, creep resistance, chemical corrosion resistance, etc. It is very suitable for the manufacture of automotive pumps, carburetor components, oil pipelines, power valves, universal joint bearings, motor gears, cranks, handles,3X3 Folding Canopy Metal Pop up Tent Shelter with Logo, window lifts, electric switches, seat belt buckles, etc., especially wear parts such as sliders are the strengths of modified POM. These parts have less wear on metals, reducing the amount of lubricant and enhancing the life of the component.

4. Polycarbonate (PC)

Modified PC has excellent heat resistance, impact resistance, rigidity and good processing fluidity.Police Car Warning Alarm Siren Horn, instrument panel peripherals, antifreeze boards, door handles, brackets, steering column sheaths,PVC Fuel Hose Flexible Propane Gas Line,New Style Men Single Shoulder Cross Body Leisure Travel Business Satchel Messenger Bag (CY1905), lamp parts, etc..

Call us on:

Call us on: Email Us:

Email Us: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.

No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.