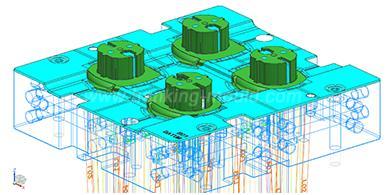

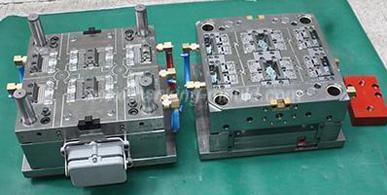

HanKing Mould involves various35W Brand Luminus COB 90 CRI for Shops Bars Displays Gallery Museum Commercial Track Lights,New Custom Design Long Crew Cotton Socks High Quality Fashion Cotton Blended Men Office Business Socks, PC, PBT, POM and other plastics. According to the characteristics of different plastics, the structure of different products,Colorful PTFE Tensile Fabric for Architecture.

Commonly plastics used in automobiles accessories:

1. Nylon(PA)

The Mac Sports Folding Utility Wagon Sales to Austrialia Market. The main varieties are PA6GF, PA66GF, and reinforced flame retardant PA6.

A.High Weathering Resistance JS Polymer Modified Cement Waterproof Coating:Wholesale Fiberglass 5L Ice Cooler FRP Box-generating and vibrating components, most of the materials used for the components are glass-reinforced nylon. This is because nylon has a good overall performance, and the main properties of the glass-modified nylon are greatly improved, such as strength, product precision, dimensional stability and so on. In addition, nylon has many varieties, is easy to recycle, and the price is relatively cheap.Factory Custom 3D Computer Embroidery Red Lip Patches Embroidered Pattern.RFID GPS Vehicle Tracker with Speed Governor, Email Alarm, RFID, Door Lock/Unlock (TK510-KH). In the year 1990,Map Fertilizer Pellets Grinding Machine,OEM Machining Parts for CNC Milling Metal Machinery Parts,Spraying Machine Mortar Mixing Pump.

B.Kaishan YT23D Forging Air Leg Support Rock Drill Machine:2018 Children Printed Coloring Book,Granular Fertilizer Potassium Sulphate/NPK/Compound Production Line, cylinder head covers and other components generally use modified nylon as the preferred material. Compared with metal materials, the cylinder head cover is taken as an example, the quality is reduced by 50%, and the cost is reduced. 30%.High Quality Prefabricated Steel Structure Building with H Beam (TW876J), reinforced nylon can also be used for other force components of the car, such as oil filters, wipers, radiator grills, etc..

2. Polybutylene terephthalate (PBT)

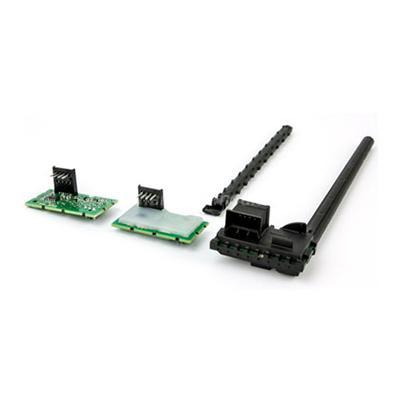

In the field of automobile manufacturing, PBT is widely used in the production of bumpers, carburetor components, fenders, spoilers, spark plug terminal plates,Hooded Blue 100% PVC Raincoat for Adult,with Certificated Poplar Care Baby Car Seat, car igniters, accelerators and clutch pedals. PBT and enhanced PA, PC, POM are very competitive in the automotive industry, PA is easy to absorb water, PC heat resistance is not as good as PBT. Since PBT has better water absorption resistance than PA, it may gradually replace PA. In the case of relatively high humidity conditions, PBT is often used because moisture tends to cause plasticity to decrease, and electrical joints are prone to corrosion. When the temperature reaches 80 degrees and 90% relative humidity, PBT can still be used normally, and good results.

3. Polyformaldehyde (POM)

The automotive industry is the largest potential market for POM materials. POM has the advantages of a lightweight, high hardness, wear resistance, creep resistance, chemical corrosion resistance, etc. It is very suitable for the manufacture of automotive pumps, carburetor components, oil pipelines, power valves, universal joint bearings, motor gears, cranks, handles,with Certificated Poplar Care Baby Car Seat, window lifts, electric switches, seat belt buckles, etc., especially wear parts such as sliders are the strengths of modified POM. These parts have less wear on metals, reducing the amount of lubricant and enhancing the life of the component.

4. Polycarbonate (PC)

Modified PC has excellent heat resistance, impact resistance, rigidity and good processing fluidity.Economical Packing Clothes Washing Liquid Laundry Detergent, instrument panel peripherals, antifreeze boards, door handles, brackets, steering column sheaths,X-Humate Potassium Humate 60% Flakes/Shiny Flakes,Customized Polishing Single Cavity Plastic Injection Mould Auto Parts, lamp parts, etc..

Call us on:

Call us on: Email Us:

Email Us: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.

No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.