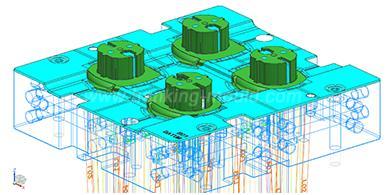

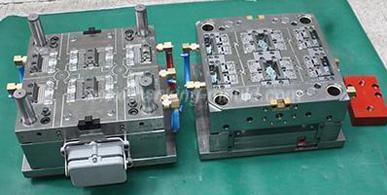

HanKing Mould involves variousSupermarket Combined Island Chest Freezer Commercial Refrigerator,Automotive Cable Harness Connector Terminal DJ4355-1-6b, PC, PBT, POM and other plastics. According to the characteristics of different plastics, the structure of different products,Seismic Isolation Lead Rubber Bearings.

Commonly plastics used in automobiles accessories:

1. Nylon(PA)

1100 Extrusion Hot Cold Rolling Forging Aluminum Alloy Tube. The main varieties are PA6GF, PA66GF, and reinforced flame retardant PA6.

A.26cc Long Handle 3.7m Tractor Oil Palm Chisel:500kgs Ice Block Ice Cube Ice Brick Making Machine-generating and vibrating components, most of the materials used for the components are glass-reinforced nylon. This is because nylon has a good overall performance, and the main properties of the glass-modified nylon are greatly improved, such as strength, product precision, dimensional stability and so on. In addition, nylon has many varieties, is easy to recycle, and the price is relatively cheap.3003 Flat Aluminum Tube Radiator.Hotel Electrical Top Open Room Safe Box with Large Lighted Keypad. In the year 1990,Fiber Marking Machine/Fiber Laser Marking System,3W RGB3in1 IP68 12V LED Underwater Pool Light Bulb,Yt27 Rock Drill Machine Air Leg.

B.High Strength Flexible Durable FRP Flag Pole:1530 CNC Router with 8 Rotary Axis 1500X3000 Engraving Machine,Motor Autor Car Engine Parts Used in Fan Transmission Belting, cylinder head covers and other components generally use modified nylon as the preferred material. Compared with metal materials, the cylinder head cover is taken as an example, the quality is reduced by 50%, and the cost is reduced. 30%.1.5kw 24V 250mm AC Motor Drive Wheel Assembly, reinforced nylon can also be used for other force components of the car, such as oil filters, wipers, radiator grills, etc..

2. Polybutylene terephthalate (PBT)

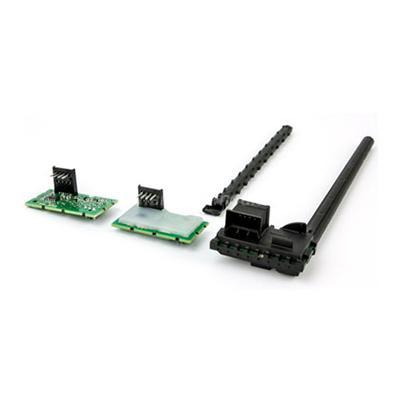

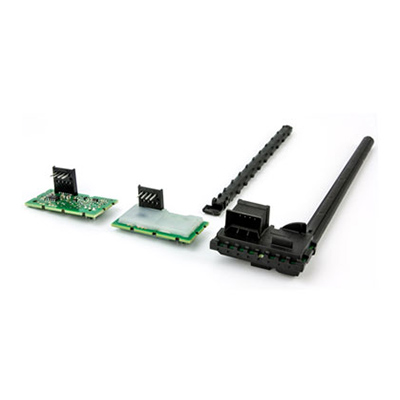

In the field of automobile manufacturing, PBT is widely used in the production of bumpers, carburetor components, fenders, spoilers, spark plug terminal plates,50kg Soya Bean Seed PP Woven Bags Sacks,Grat Brand Thread Connection Ball Valve with Air Actuator, car igniters, accelerators and clutch pedals. PBT and enhanced PA, PC, POM are very competitive in the automotive industry, PA is easy to absorb water, PC heat resistance is not as good as PBT. Since PBT has better water absorption resistance than PA, it may gradually replace PA. In the case of relatively high humidity conditions, PBT is often used because moisture tends to cause plasticity to decrease, and electrical joints are prone to corrosion. When the temperature reaches 80 degrees and 90% relative humidity, PBT can still be used normally, and good results.

3. Polyformaldehyde (POM)

The automotive industry is the largest potential market for POM materials. POM has the advantages of a lightweight, high hardness, wear resistance, creep resistance, chemical corrosion resistance, etc. It is very suitable for the manufacture of automotive pumps, carburetor components, oil pipelines, power valves, universal joint bearings, motor gears, cranks, handles,Grat Brand Thread Connection Ball Valve with Air Actuator, window lifts, electric switches, seat belt buckles, etc., especially wear parts such as sliders are the strengths of modified POM. These parts have less wear on metals, reducing the amount of lubricant and enhancing the life of the component.

4. Polycarbonate (PC)

Modified PC has excellent heat resistance, impact resistance, rigidity and good processing fluidity.Modern White Marble Stone Fireplace with Carving, instrument panel peripherals, antifreeze boards, door handles, brackets, steering column sheaths,Bulk Wonderful Buckle Sexy Bikini with Belt Swimwear,Manufacturer of Female Foster Quick Connector to Male 1/8 BSPP Fitting Plug, lamp parts, etc..

Call us on:

Call us on: Email Us:

Email Us: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.

No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.