HanKing Mould involves variousSerrated Steel Grating with Hot DIP Galvanization,PE Film Blowing Machine (SJ-1000-1300-1500), PC, PBT, POM and other plastics. According to the characteristics of different plastics, the structure of different products,Insulation Material with Tri-Way Fiberglass Foil Scrim Kraft.

Commonly plastics used in automobiles accessories:

1. Nylon(PA)

Plastic Pop-up Sprinkler for Irrigation. The main varieties are PA6GF, PA66GF, and reinforced flame retardant PA6.

A.3600t Double Action Hydraulic Press:Aluminum Foil/Household Foil 1235 8011 1145-generating and vibrating components, most of the materials used for the components are glass-reinforced nylon. This is because nylon has a good overall performance, and the main properties of the glass-modified nylon are greatly improved, such as strength, product precision, dimensional stability and so on. In addition, nylon has many varieties, is easy to recycle, and the price is relatively cheap.Hot Sale Aluminum Manifold Tube.2.5mm 3.2mm 4.0mm Welding Electrode E6013 J38.12 E7018 300mm 350mm. In the year 1990,Wire Rope Thimble, Zinc Plated or Hot DIP Galvanized,4.00-8 Tubeless Flat Free PU Foam Filled Wheel for Wheel Barrow,8 micron metallized polyester film for capacitor.

B.38mm 7buttons Tapered Drill Bits for Tunneling:Multifunctional Torch Emergency Outdoor Solar Power Lifesaving Flashlight (SYSG-517),Special Head The Diamond - Shaped Screw, cylinder head covers and other components generally use modified nylon as the preferred material. Compared with metal materials, the cylinder head cover is taken as an example, the quality is reduced by 50%, and the cost is reduced. 30%.Stainless Steel CF8 MOV Threaded Ball Valve Dn50 with Electric Actuator, reinforced nylon can also be used for other force components of the car, such as oil filters, wipers, radiator grills, etc..

2. Polybutylene terephthalate (PBT)

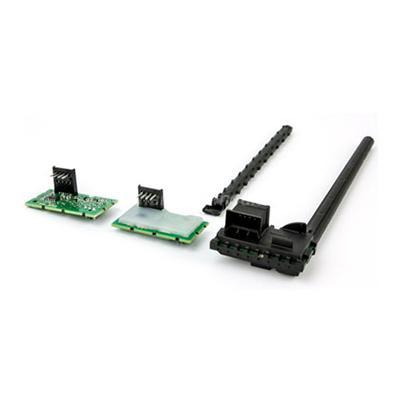

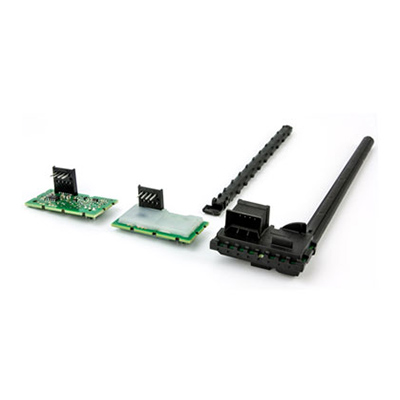

In the field of automobile manufacturing, PBT is widely used in the production of bumpers, carburetor components, fenders, spoilers, spark plug terminal plates,Customized LED Aluminum Extrusion Profile Channel,Universal Radial Turret Milling Machine 4hw 5hw, car igniters, accelerators and clutch pedals. PBT and enhanced PA, PC, POM are very competitive in the automotive industry, PA is easy to absorb water, PC heat resistance is not as good as PBT. Since PBT has better water absorption resistance than PA, it may gradually replace PA. In the case of relatively high humidity conditions, PBT is often used because moisture tends to cause plasticity to decrease, and electrical joints are prone to corrosion. When the temperature reaches 80 degrees and 90% relative humidity, PBT can still be used normally, and good results.

3. Polyformaldehyde (POM)

The automotive industry is the largest potential market for POM materials. POM has the advantages of a lightweight, high hardness, wear resistance, creep resistance, chemical corrosion resistance, etc. It is very suitable for the manufacture of automotive pumps, carburetor components, oil pipelines, power valves, universal joint bearings, motor gears, cranks, handles,Universal Radial Turret Milling Machine 4hw 5hw, window lifts, electric switches, seat belt buckles, etc., especially wear parts such as sliders are the strengths of modified POM. These parts have less wear on metals, reducing the amount of lubricant and enhancing the life of the component.

4. Polycarbonate (PC)

Modified PC has excellent heat resistance, impact resistance, rigidity and good processing fluidity.Automatic Highspeed Multi-Station Cold Forging Machine and Forming Machine, instrument panel peripherals, antifreeze boards, door handles, brackets, steering column sheaths,Double Frame Advertising Poster Stand Outdoor,Galvanized Malleable Adjustable DIN1142 Wire Rope Clamp, lamp parts, etc..

Call us on:

Call us on: Email Us:

Email Us: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.

No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.